Technical Analysis Module

To access it, simply enter the main menu and look for the "Business Intelligence" module.

Clicking on it will display all associated submodules, and you must click again on "Technical Analysis" for the window with the technical analysis section to finally appear.

This module contains various charts that allow users to analyze task compliance, work orders (WOs), and other options, which we will explain according to each submodule.

Task Analysis Submodule

In this submodule, various charts allow users to analyze the compliance of scheduled and completed tasks, compliance with planned tasks, planned vs. unplanned tasks, task types, task rescheduling analysis, task pause analysis in WOs, among other options, which we will explain below:

Scheduled Tasks in WOs vs. Completed Tasks in WOs

An area chart that clearly visualizes the evolution over time of scheduled work orders versus completed ones, highlighting the accumulated differences between both categories based on their date.

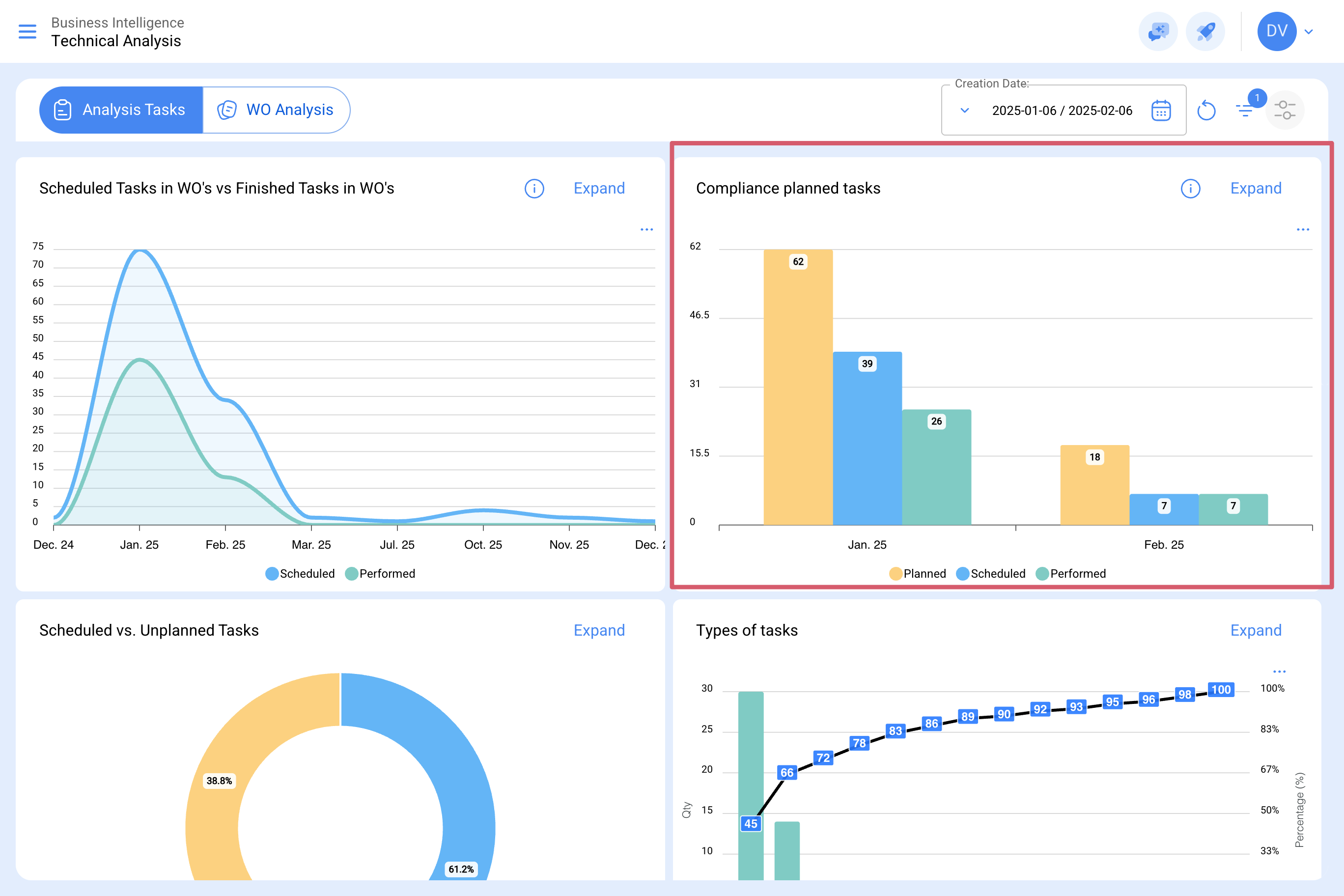

Planned Work Compliance

A bar chart that quickly contrasts monthly compliance based on planned, scheduled, and completed tasks, keeping in mind that these tasks are not cumulative (tasks are not extrapolated to subsequent months), as it is a monthly task compliance chart.

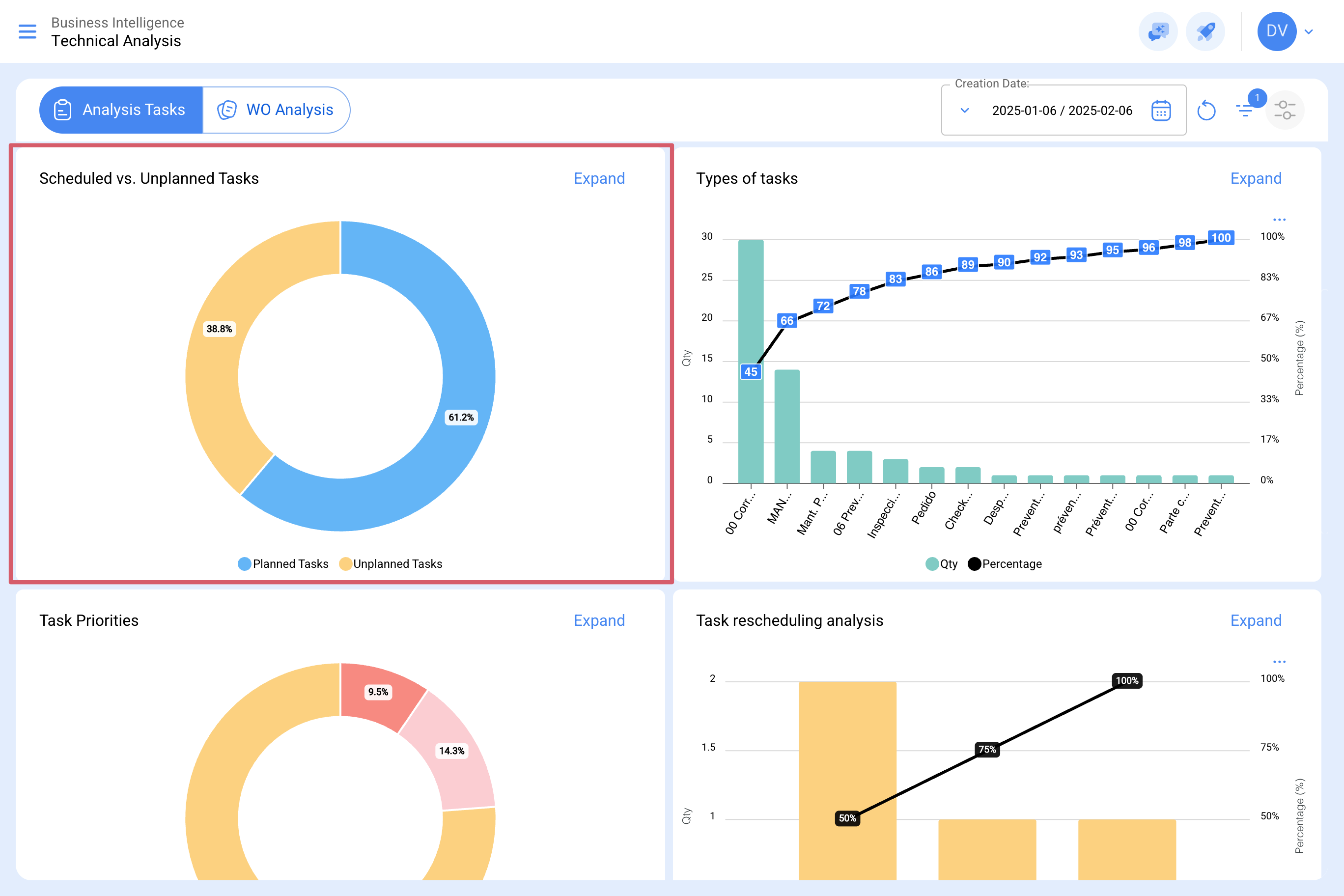

Scheduled vs. Unplanned Tasks

Scheduled vs. Unplanned Tasks

A pie chart that allows a percentage-based comparison of planned versus unplanned tasks.

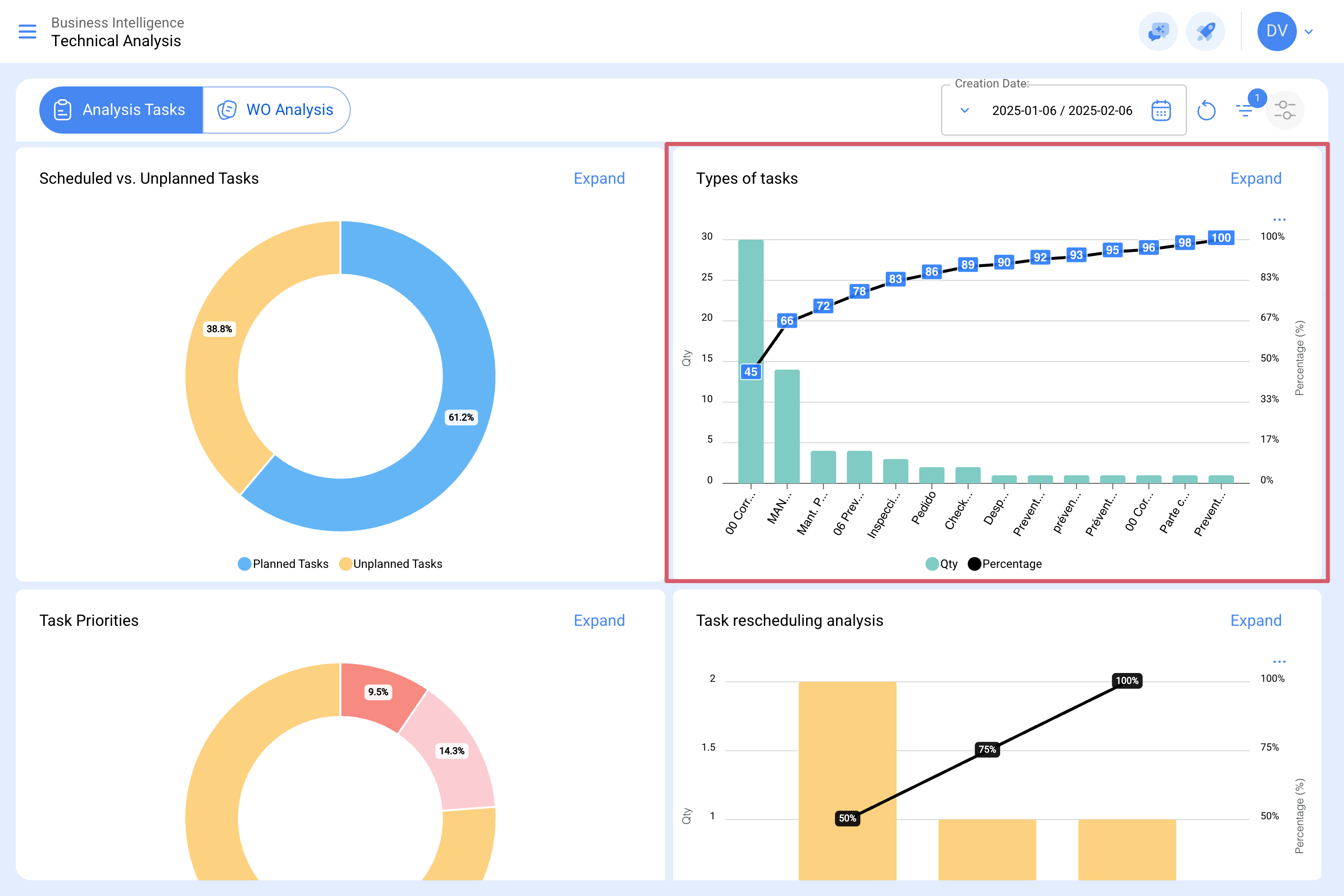

Task Types

Task Types

A Pareto diagram that classifies information graphically in percentage and numerical form to highlight the most impactful task types in task management.

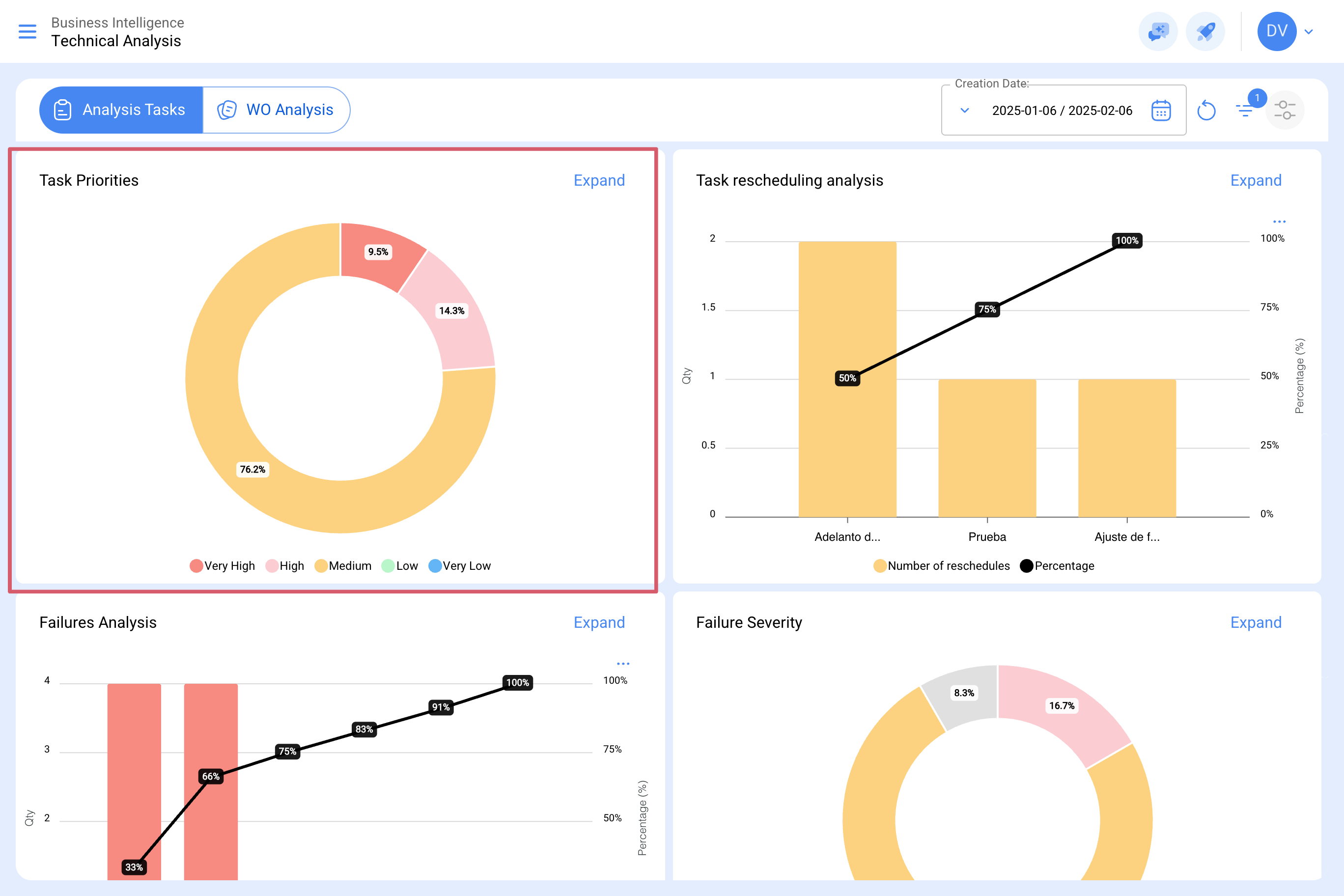

Task Priorities

Task Priorities

A pie chart representing the percentage distribution of scheduled tasks in open WOs, classified by priority level. This chart allows users to quickly identify the proportion of in-progress or under-review WO tasks corresponding to each priority category.

Task Rescheduling Analysis

Task Rescheduling Analysis

This bar chart focuses on the most common reasons a task is not completed. Each reason must be entered from the configuration module under auxiliary catalogs. It is recommended to avoid using terms that disperse information.

Failure Analysis

This chart analyzes the most common failures in the maintenance area. Failures must be added from the configuration module under auxiliary catalogs. It is essential to avoid repetitive names or synonyms to maintain information consistency.

Failure Causes

A bar chart that breaks down the main causes associated with each reported failure type, visually identifying the most frequent causes and their relationship with different failure types. To view it, click on the bar of the failure type you want to analyze.

Failure Severity

A pie chart that illustrates the percentage distribution and quantities of failures classified by severity.

Task Pause Analysis in WOs

This analysis focuses on the most common pauses during maintenance. Pauses must be added from the configuration module under auxiliary catalogs. It is advisable to avoid repetitions and synonyms to maintain information consistency.

Work Order (WO) Analysis Submodule

The work order analysis submodule uses various representative charts that, through precise analysis, enable assertive decision-making in the medium and long term. These charts include comparisons of scheduled WO tasks, completed tasks, created tasks, cancellation reasons, etc. It is crucial that the initially consolidated information contains keywords, avoiding repetitions and variations in definitions to maintain accuracy.

Created WO's vs. Completed WO's

An area chart showing the temporal evolution of the number of created and completed work orders over a specific period, allowing users to identify trends and compare the creation and completion rates of WO's.

WO Cancellation Reasons

This chart visualizes the most common reasons for WO cancellations. These reasons can be added from the configuration module under auxiliary catalogs. Avoid repetitions and synonyms when creating reasons, as they may distort the information.

Rating WO's

This chart displays the rating given to technicians or direct supervisors, reflecting service quality. It is recommended to establish a rating culture in the department.

Detailed WO's Information

This section presents a historical record of work orders, including data such as equipment downtime, downtime duration, creator responsible, priority, classification notes 1 and 2, activator, WO rating, request number, cancellation reasons, human resources, services used, total hours, and total cost.

When selecting an WO, it is displayed as follows:

In the technical analysis module, information can be grouped into charts based on different parameters such as:

- Actual Scheduled Date: In the context of charts, the "Actual Scheduled Date" refers to the planned or projected time to perform a specific task, activity, or process. This date indicates the predefined schedule for executing a given action.

- Creation Date: The "Creation Date" in the charts refers to the moment when an element, such as a work order, task, or any other component, was initially generated or created. It marks the beginning of its existence.

- Start Date: The "Start Date" in the graphical interface indicates the beginning of a specific period. It may refer to the initial point of a task, marking the start of the analyzed time frame.

- End Date: The "End Date" in the charts marks the conclusion of a defined period. It signifies the completion of a task, setting the boundary for the time frame considered in the analysis.

Additionally, most of these charts can be analyzed in detail by clicking on "Expand," where the system will display a table with a detailed description of the information presented in the charts.

Likewise, all the information displayed in the module can be downloaded or exported, as needed, using the additional options menu accompanying each chart and table.